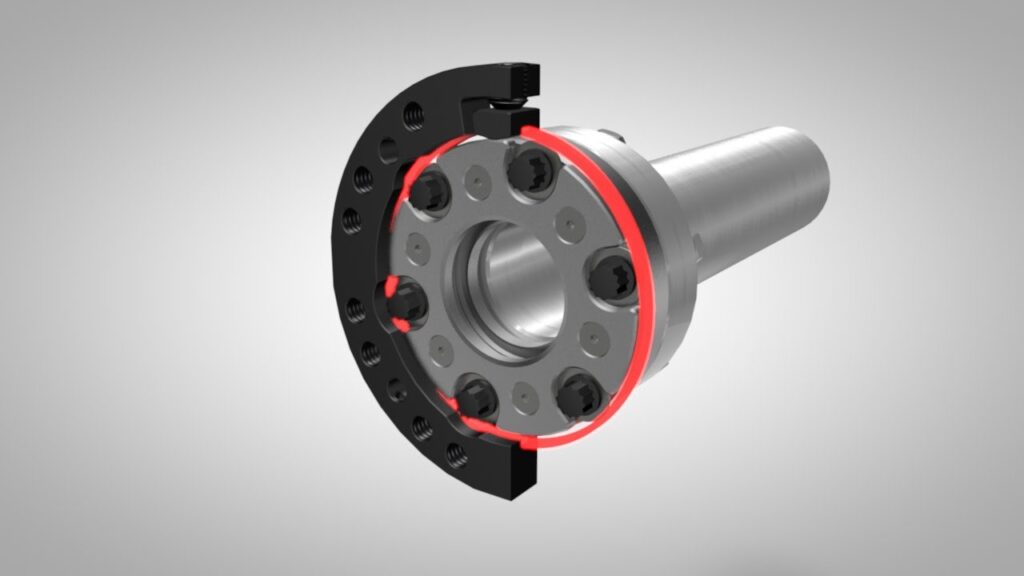

Flanges are extended ridges or rims, either external or internal. These things are used for guiding surging strengths or machine parts for easy attachments to other objects. It can also be a ring or a plate to create different kinds of flanges: steel pipe, pipe, weld neck, lap joint, slip-on, spectacle blind, blind, and others.

CF flanges or ConFlats are sexless designs where both designs are all the same. These things are flanged attachments for ultra-high vacuums and are equipped with static metal seals that can fight high-temperature baking. Standard flanges are usually manufactured from surface-hardened and stainless steel-types aluminum.

Check out this site to find out more about these devices.

But they also come in different stainless steel grades and can be modified depending on the client’s preference and taste. ConFlat flanges can provide complete coverage for vacuum-chamber systems. These devices use oxygen-free high thermal conductivity copper gaskets that are knife-edge machined under their flat surface to enhance tight seals.

These knife edges can make a circular grove on both sides when flange-pair nuts are properly fastened. It penetrates into softer copper gaskets to create leak-tight and metal-to-metal seals. These things are readily available in four versions: Clearance holes, Tapped holes, Rotatable, and Fixed.

How to torque CF flanges properly

Torquing is the concept of force or the amount of energy needed for objects to rotate – this includes flywheels and nuts. Torque is required in order to get stable connections. For example, to get a fluid transmission with no leakage, the proper gasket installation is required, and bolts should be tightened into these devices with the right balance and tension over the entire flange face. Torque will develop tension that can fix two components so they can repel sliding or pull apart. Proper torquing of ConFlat flanges requires:

Making the flange Metal to Metal

A lot of individuals using ConFlat flange tighten nuts until the surfaces of the device come in contact with each other. These devices respond by offering built-in gauges to establish when gaskets have been sufficiently deformed. But there’s the possibility of over-tightening these nuts when people apply this technique.

How do these devices work? Visit https://www.sciencedirect.com/topics/earth-and-planetary-sciences/flange for more info.

Tightening bolts to a certain torque

Most of these manufacturers provide a pre-approved value of the bolt torque. While there’s an excellent harmony for larger sizes, there’s a notable spread in the pre-approved torque for smaller devices. So, what is the right value to use? As bolts are fixed, some power is used to these gaskets, and an opposite and equal tensile stress is used to these nuts.

The best rule of thumb is that these things may be tightened. The stress can stretch up to 75{b184f1c5c83e4e631390653e42e561084d020accf3208d58bfa88d5a3bad72b9} of the yield stress of materials used. While it may be pretty hard to compress gaskets with less torque, shifting bolts to the value will compromise the strength or integrity of these nuts, and there is minimal incentive to use a lower value. Effective tightening of bolts on ConFlat flanges needs the right equipment for the job.

The equipment will be used for various applications. For example, torque wrenches exert tension on bolts, nuts, and screws to fasten the two parts securely. These things are used to avoid popular under-tightening or over-tightening, which can bring about costly restorations later on. To make sure people do the right torquing, they need to follow the procedures listed below:

Modify wrenches to the recommended setting that manufacturers listed – It entails loosening tighteners at the end of the tools’ handles, checking the dimension of the tools, setting it in the right setting, as well as locking the correct setting.

Check cleaning – make sure that the rusted and dirty threads are thoroughly cleaned you tighten the nuts.

Lubricate threads – For the right lubrication, make sure that the ConFlat fitting is well lubricated, with the right lube present on every thread, as well as beads of lube coming out of the nut.

What is the correct tightening sequence?

When you tighten a bolt, experts recommend fixing them in rows. It is because tightening these things singly disorient preloads on other bolts in their group. But caution needs to be taken to avoid over-tightening, thus causing a significant leak.

Circulars are tightened using a crisscross method, while non-circular nuts are tightened in the spiral tightening way. First, tighten these things partially, then crisscross them to the next bolt while repeating the procedure. After all, these things will be tightened partially; repeat to complete the tightening process.